Detail Product

Hand-Pushed Concrete Saw Wet Type

Safely designed according to safe standards set forth in relevant Japanese Industrial Standards. With high rigidity and low center of gravity, these products achieve excellent cutting.

Features

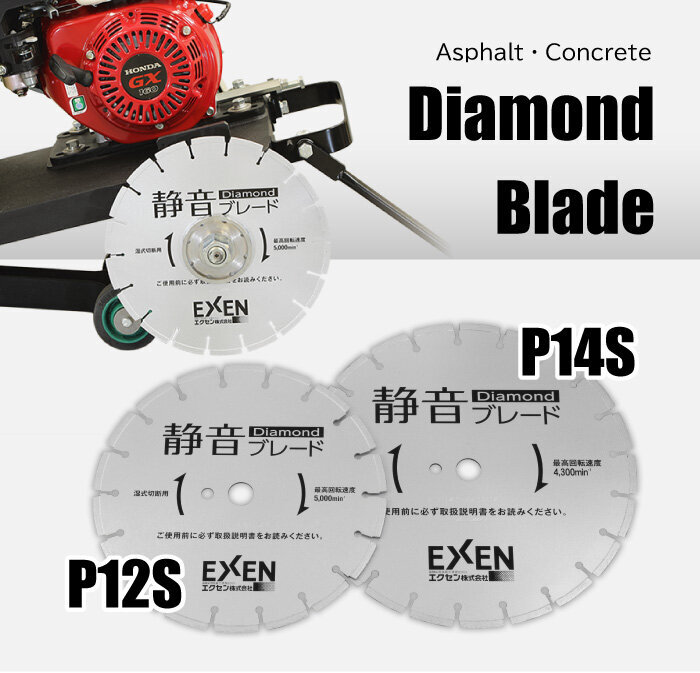

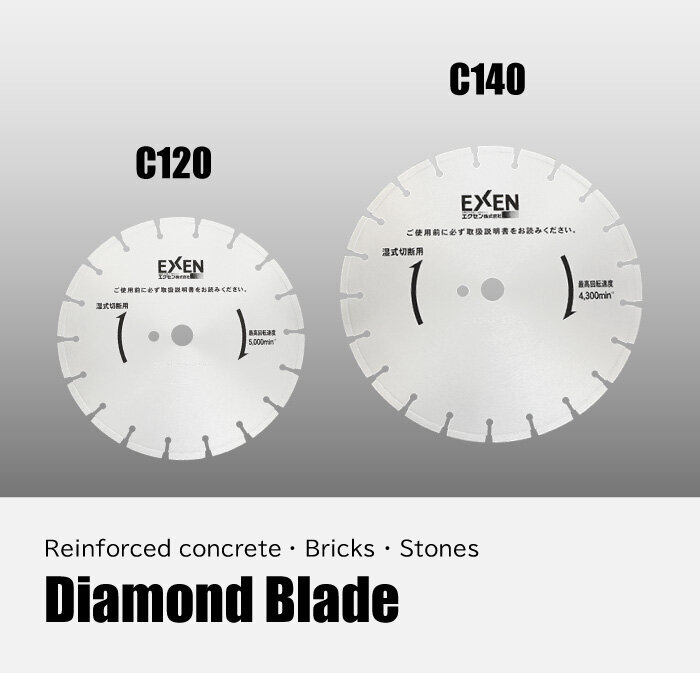

This Exen hand-pushed concrete saw emphasizes cutting performance, durability, rust‐prevention, and safety. The ECR12CC chassis is made of newly designed sheet metal machined product. With the chassis of ECR12E to 14C made of ductile cast iron, these products are machined with high precision, high rigidity, and low center of gravity to achieve stable operability and excellent cutting capacity. This concrete cutter achieves particularly high worker safety by being designed to meet adequately the safety requirements for JIS-compliant road works machinery. Also available are optional blades (for asphalt and concrete), diamond blades (P/C series), designed specifically for the ERC series.

- Designed to meet adequately the work requirements for road works machinery

Safely designed according to the requirements of the safety standards for JIS-compliant road works machinery, achieve high work safety.

- Excellent cutting performance

A body-supporting component and therefore the most important, the chassis is made of newly designed sheet metal machined product (12CC) and ductile cast iron (12E and 14C), with highly precise machining, high rigidity, and low center of gravity, thereby achieving stable operability and cutting performance.

- co-friendly engine

Equipped with “High Power HONDA GX”, an eco-friendly engine that complies with the self-imposed control of exhaust gas.

- In pursuit of durability and rust‐prevention

Rust-resistant stainless steel (SUS) is used for the blade case to pursue durability and rust prevention. (Example: ERC14C = 14 inch size can be installed.)

- Equipped with a large-capacity water tank (with a punch plate)

These products come equipped with a large-capacity polypropylene tank of the largest order of its class, robust and durable, which cannot gather rust and allows disconnection without keeping a hose attached from outside at all times.

- Equipped with a 3VX

3V reduces the incidence of belt breaks and revolution losses.

- Blade attachment made easy

The blade case is so structured as to be installed in a single touch, which facilitates blade attachment. (Excluding 12CC) ERC12CC has a structure that the blade case opens.Standardized at a diamond blade shaft hole diameter of 27 mm for all models.

Note) The model number is the size of the maximum diamond blade that can be installed to it (in inches). (Example: ERC12CC = 12 inch blade can be installed.) In addition, the diamond blade P / C series (for asphalt / concrete) exclusively for the ERC series is available. (Sold separately) - Improved blade cooling efficiency by centrifugal water discharge

The blade holder is of the centrifugally dispersion type that allows cooling water to reach all corners of the blade by centrifugal force. This increases cooling effect, along with cutting performance and blade life. (Excluding 12CC)

- Equipped with engine throttle lever as standard

Equipped with a throttle lever that can adjust the engine rotation at hand as standard. (Excluding 12CC)

- Screw type move up and down handle

Uses a safe screw type that prevents blade damage due to rapid cutting.

- Equipped with a guide arm

The standard guide arm makes it easy to see the cutting position. The position of the guide bar can be set freely. (Excluding 12CC)

- Telescopic foldable running handle Convenient for transporting.

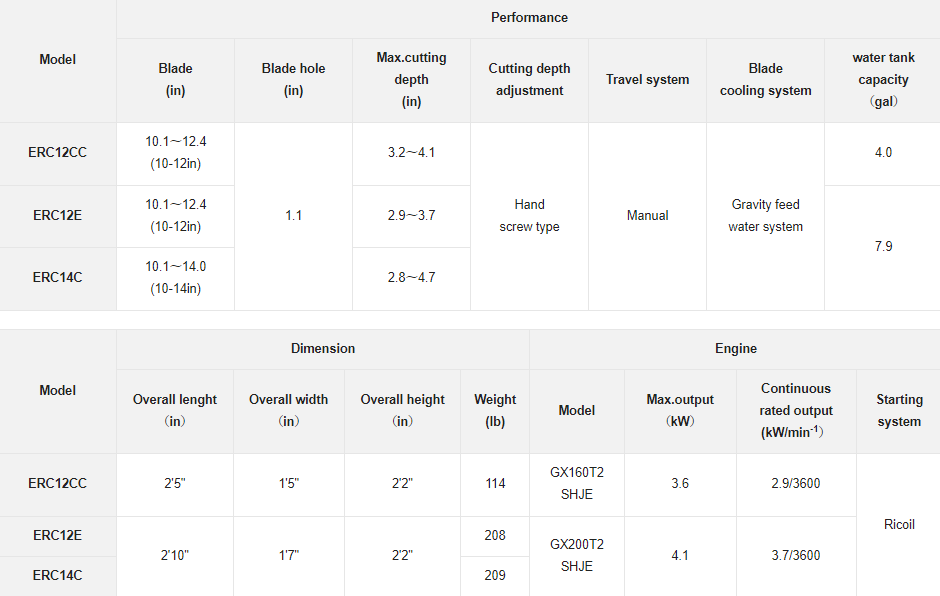

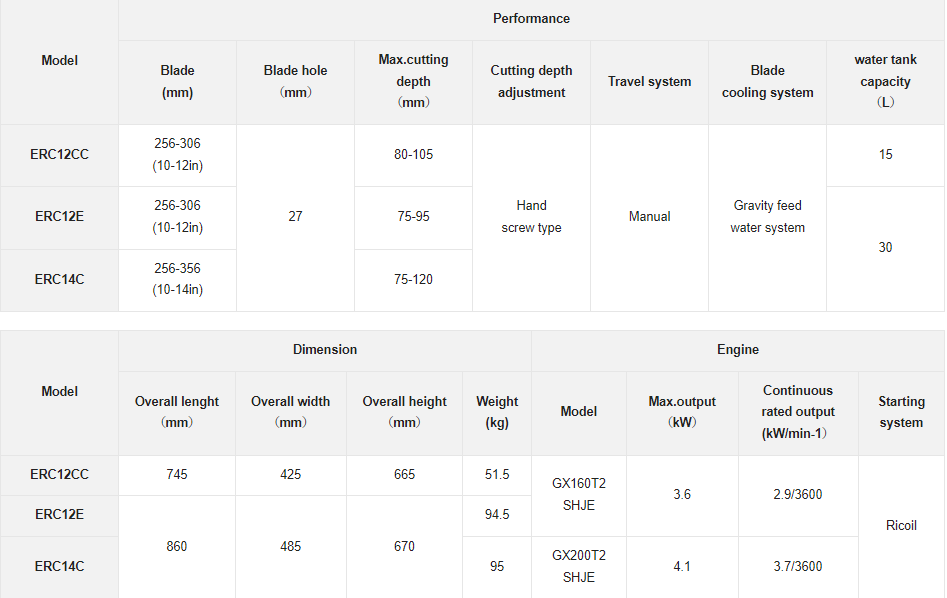

Specification